A few years ago i tried re-bushing a spare throttle body using Delrin as the bushing material. I couldn’t get the throttle action smooth, it seemed as if the Delrin had a stiction property that I just couldn’t over come either by sizing the bushing or lubricating. So I laid the project aside and forgot about it.

Then this last summer I noticed some play in the shaft of the throttle body installed in the van. There was enough play to make adjustment of the throttle position switch very fussy. So i though back on my previous experiment and I thought I’d try making bushings again, but this time out of HDPE.

First let’s go back to my spare throttle body, the one I re-bushed with Delrin. I have a blog post here showing it before I started screwing around. I even went as far as cleaning up the wear marks in the bore and making a new butterfly plate to compensate for the now enlarged bore.

See the Delrin bushing?

And on the other side, the throttle position switch side.

My daily driver one on the left, the re-furbed one on the right.

Not the larger cam on the one on the left. This is the newer, revised throttle position switch system.

It appears like a lot of space around the butterfly, but it really isn’t that bad. I can’t recall the gap size (I measure with wire).

It kinda looked ok to me.

The dried up seal on one side.

And the other.

Wear in the bore from the butterfly.

I decided to leave bore and the butterfly untouched. I chucked up a hunk of polyE and turned and reamed a couple of bushings.

Recessed on the throttle position switch side.Why? because the switch plate has little locating tabs that fit into the hole.

Pretty well flush on the other side.

Gosh, i can’t recall for sure the butterfly shaft diameter, maybe it was 8 mm, yeah I think so. I do have an 8mm reamer. Anyhow, I did think about bearings instead of bushings. But the bearings I had on hand had a larger OD and that would have meant taking the throttle body to work to use the milling machine; tedious set up and then a boring head.

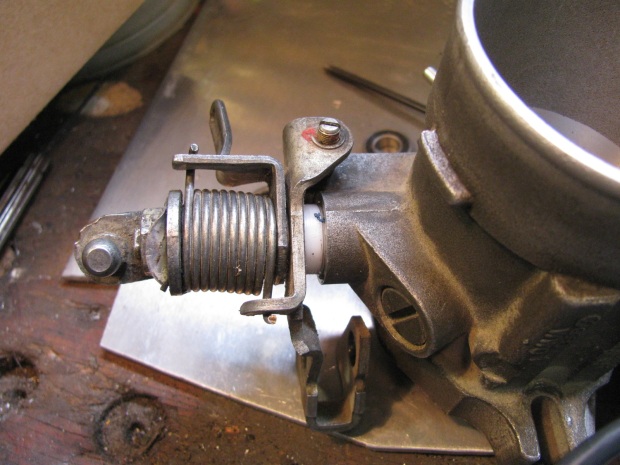

Assembled. I have to say the action of the butterfly is smooth as silk, much better than the Delrin. Come to think about, I wonder if I reamed the bushings the last time?

The throttle position switch now is easier to set, there is no wobble in the butterfly shaft.

#1 by edbee on September 14, 2014 - 9:29 am

Hi Al, nice work as always 🙂

#2 by albell on September 14, 2014 - 9:58 am

Thanks Ed,

You know I keep meaning to email you to discuss something, you know, that nightmare samba thread.

Cheers

Ab

>