A week and four (!) attempts later I finally have the leak fixed. It’s a tale of woe and I guess you could say blindness on my part. When I re-installed the cover plate and noticed the drip at one of the lower cover bolts I assumed the leak was coming from a poor seal at the plate. So I drained the oil and left the cover plate off overnight. Next day I cleaned the mating surfaces well with brake cleaner and used Permatex grey RTV on the sealing surface. Filled the transmission and it still leaked, a small drip at one of the cover plate lower bolts. Now I was peeved. Emails to Daryl at AA Transaxle gave me some confidence, he suggested that I make sure that the cover plate was flat and that the 6 mm socket head bolt under the cover plate was good and tight. So once again I drained the transmission (cover plate off again) overnight. Next day I set about making sure the cover plate sealing surface was flat. I tried flat filing but even with the file loaded with chalk, aluminum filings would ball up and scratch the surface.

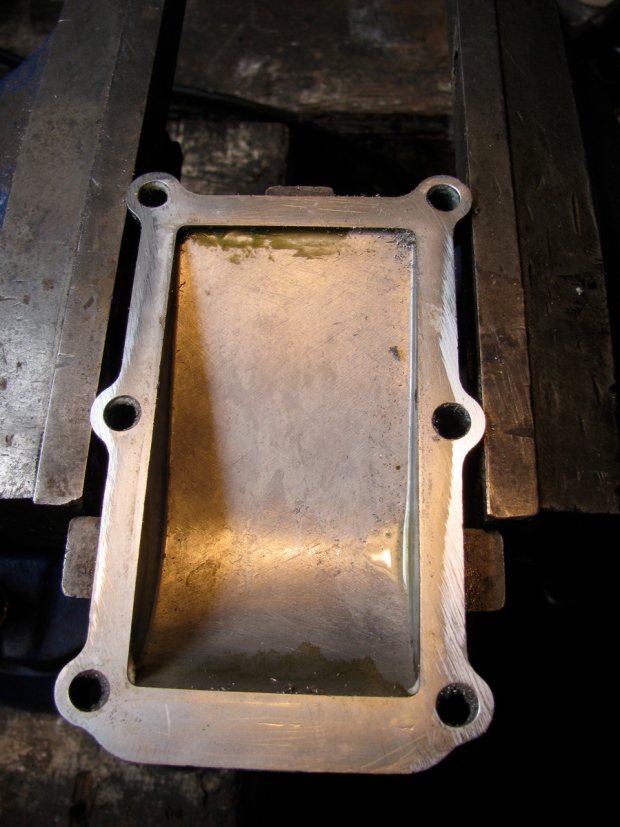

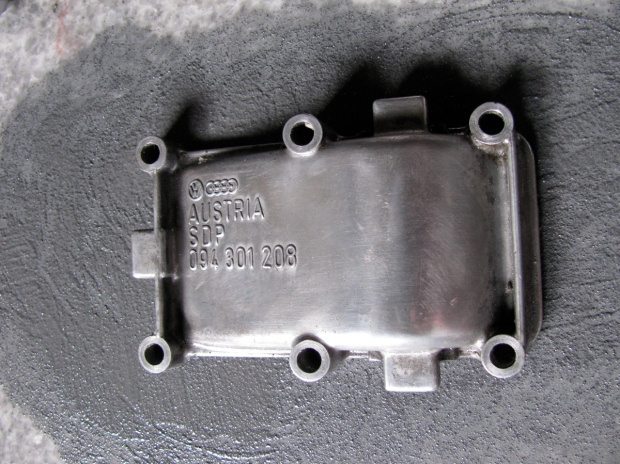

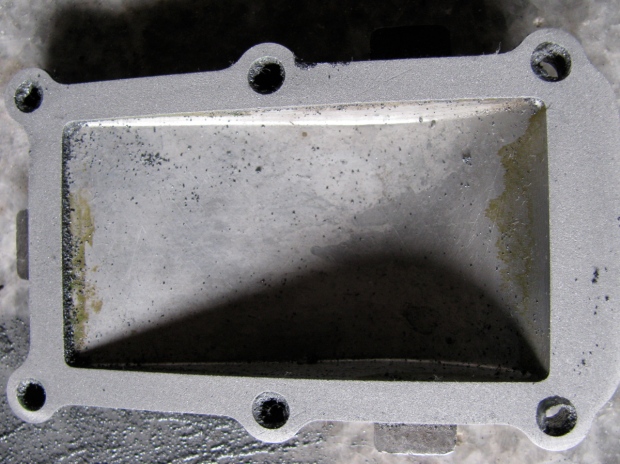

So I switched to lapping the cover on a bit of granite using a couple of grades of carborundum grit and WD40 as a lube.

Coarse grit:

Finer grit:

You can see a few larger scratches, must have had some coarse grit carried over. But that doesn’t really matter in this situation, what I wanted was the the cover plate sealing surface to be flat.

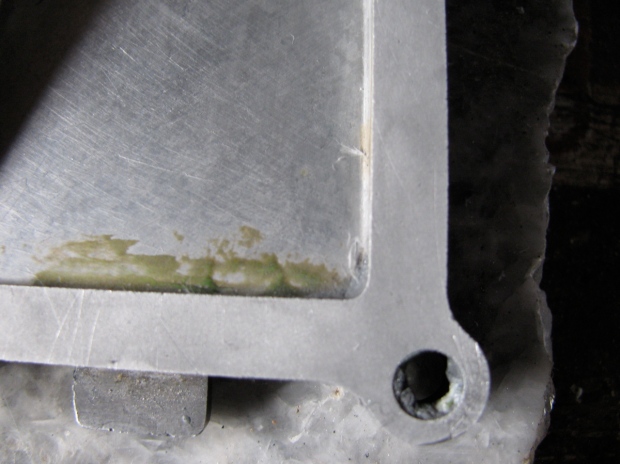

Back at the transmission I removed the old silicone sealant which what I thought was squeeze out from the original install of the cover plate, right adjacent to the cover plate hole rear side. This was where I was blind, I should have thought more about why there was so much clear silicone there. I also carefully filed what I thought were slight ridges around the bolt holes on the cover plate sealing surface. Here is an example (you might guess that I was grasping at straws here):

Filed:

As another example of me being gormless, I even smeared some RTV on the area where I removed the old silicone caulk on the case seam. Why did I not put more on and further up the seam? I don’t know.

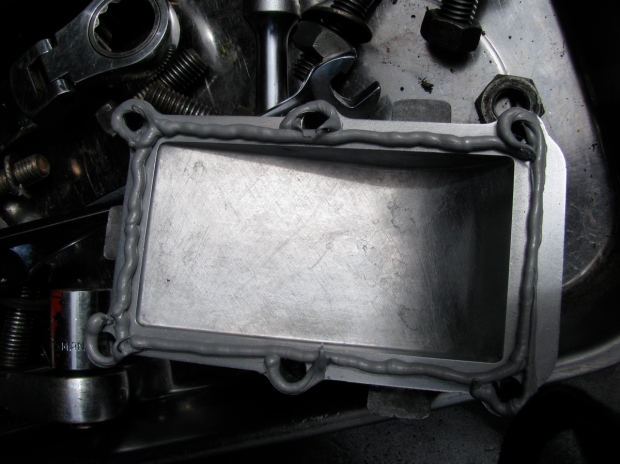

Cover plate was caulked and put into place.

I was generous with the caulk – well that’s what I have been told 🙂

I let the stuff cure for about 5 hours before I filled the transmission with oil. Can you guess what happened? Yes, still a little drip. Chagrin does not adequately describe my feelings at this point. I went under the van and looked carefully and I noticed oil seeping out from the top edge of the little it of RTV I smeared on the case joint (pictured above). If I put a corner of a rag on that spot the drip at the lower bolt would stop. Why had I not noticed this before. More info from Daryl and a sinking feeling that I might have to pull the transmission and reseal the case joint. But I decided to make one more attempt. Again, an overnight drain of the oil and this time I scrubbed and degreased the case joint all along the side of the cover plate hole. I bought some of the expensive RTV sealant, “The Right Stuff”, it had a few good recommendations and is a fast curing goop.

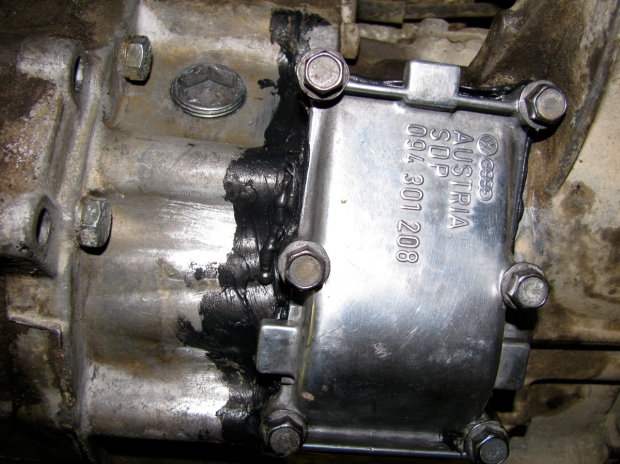

Picture here of the cleaned area (cover plate sealing surface was later cleaned of the old grey Permatex):

I also gave that socket head bolt another bit of twist. Then I smeared on sealant over the case joint, and on the cover plate sealing surface, not very pretty:

I let the stuff cure for a few hours then refilled the transmission and went into town on errands. I was not optimistic about success, but I’ll be dammed if the damn thing is now sealed tight! One day later and it is still dry. I’ve come to the conclusion that the original silicone caulk that I removed from the case joint area was put on to stop a leak. I bet it was done when the transmission was rebuilt.

I learned a few things from this fiasco. Apart from being more observant I discovered that when putting on the skid bars/plate on the syncro, install the bolts loosely until all are in place, before tightening. That makes it so much easier. I also found that my Snap-On transmission wrench (17 mm hex) was awkward to use on the fill plug (but very good on the drain plug) so I cut a section off my 17 mm allen key and used the short bit on a 17 mm socket, and even better, on my 17 mm ratcheting spanner.